*Disclaimer*

The information contained on this page is for promotional and informational purposes only. All equipment should be used by trained professional tradesmen who have been trained how to use the equipment described on this page, and understand the risks of their work. PowerPak assumes no responsibility for errors or omissions in the use or misuse of any product purchased. In no event shall PowerPak be liable for any direct, special, indirect, consequential, or incidental damages or any damages whatsoever, whether in an action of contract, negligence or other torts, arising out of or in connection with the use of this information or the contents of this page. PowerPak reserves the right to make additions, deletions, or modifications to the contents on this page at any time without prior notice.

There isn’t much you can say about hard hats that every construction worker doesn’t already know. You put it on your head and if it does its job, you get to go home at the end of the day, unharmed.

Honestly, that’s all you really NEED to know. If you always wear your hard hat when you are supposed to, you’re doing great.

But if you are interested in learning if you have the right kind of head protection, when and where are hard hats required, or what exactly do they protect you from, you should keep reading. We are going to do our best to answer all of those question and more.

What are they?

Hard hats are helmets designed for work environments such as manufacturing, industrial and construction sites to protect the head from injury. The outside shells are usually made from high-density polyethylene (HDPE) or a polycarbonate resin as they are strong, easy to mold, lightweight, and do not conduct electricity. The shell is rigid, and its main purpose is to deflect blows to the head.

They come with a suspension system made of woven nylon webbing strips and bands of nylon, vinyl, or molded HDPE. The suspension system and the internal foam lining serve as a shock absorber and an insulator against electrical shocks. Some helmets also feature a shield for your face and neck to prevent contact with any harmful materials.

When are Hard Hats Required?

There are a couple of different ways to answer this question. Most employers want to avoid fines and need to know what OSHA requires.

The Occupational Safety and Health Administration (OSHA) rules state that hard hats must be used whenever there is a possibility of head injury from impact and penetration, or from falling or flying objects, or from electrical shock and burns.

That’s a fairly broad statement and doesn’t really clear up the specifics of what OSHA expects. In 2004 Bret Barnard wrote a letter to OSHA’s Directorate of Construction (Russell Swanson), asking for clarifications for his specific work conditions.

Bret explained that his roofing workers wear hard hats to get on and off the roof, but while on the roof, they remove the hard hats because none of the OSHA defined risks are present.

Mr. Swanson agreed that the workers were NOT in violation of OSHA regulations 29 CFR 1926.100. Which is surprising, considering these workers are on an active jobsite and are not wearing head protection.

Head protection related OSHA violations come down to decisions based on a hazard assessment. If an adequate hazard or risk assessment has been made the resulting decisions are difficult to fine.

BUT the OSHA regulation is only one part of hard hat requirements. If you’re familiar with the term “My house, my rules”, you know what’s coming up.

Employer hard hat requirements are often much stricter than the OSHA requirements. In the example with Mr. Barnard and his roofers, the roofers were not in violation of the OSHA regulation, but they were in violation of the GC’s jobsite policy.

There are a number of reasons why an employer would implement a stricter policy, and those reasons could include insurance requirements, regulations set by local government or property owners, or simply from past experiences.

Examples of some industries that you’ll often expect to wear head protection include:

- Construction

- Mining

- Oil and gas

- Utilities

- Cutting and logging

- Freight handlers

- Sometimes in Manufacturing and packaging

Hard Hats Prevent Injuries and Save Lives

The story goes as follows, in 1919 a San Francisco company, E.D. Bullard Company, now known as Bullard, modified doughboy army helmets to fit the function of protecting mine workers from falling debris. It worked, and it worked so well that a decade later, hard hats were required PPE during the construction of the Golden Gate bridge to protect workers from falling rivets. Again, it worked, saving lives, and preventing unnecessary injury.

That was over 100 years ago, and although the design and technology behind hard hats have developed, the basic idea is the same. The main reason for wearing hard hats is to protect yourself from head or brain injuries which can cause concussions and have long-term effects on your physical and mental health. In the worst-case scenario, traumatic brain injuries can even lead to nerve damage, paralysis, or death.

Worker’s that choose not to wear head protection often do so supported by the thought, “What are the chances”. Well, if you work in construction, the risk is high. Even with regulations in place nearly 1000 workers died in 2019. When it comes to head injuries, the goal is to avoid TBI (traumatic brain injuries), which have a high probability of resulting in death or severe disabilities. TBI’s can be caused by object falling on you from above, walking into objects and other side impact occurrences, or tripping and falling causing head injuries. In many cases, the use of head protection would prevent serious head injury in any of these hazards.

Training

Employers are responsible for providing their employees with hard hats that comply with the job requirements and provide sufficient protection considering the nature of work. It is also the employer’s responsibility to train their workers to use and maintain their hard hats. Typically, the training should include:

- The purpose of hard hats

- The hazards hard hats protect from

- Functioning of the hard hat

- Limitations of hard hats

- When hard hats must be worn

- Proper usage of hard hats, including the right way to wear one

- Adjusting the fit of hard hats for comfort

- Proper storage for hard hats

- Identifying signs of wear or damage

- Hard hat cleanliness and maintenance

How To Wear Hard Hats Properly for Maximum Head Protection

- If you wish to wear any clothing item under your hard hat, make sure it is a specially designed hard hat liner and not just any other material, so it does not affect the functionality of your hard hat.

- The bill of the hard hat should point towards the front of your head. If the cap is worn backwards, it compromises the effectiveness and fit, unless otherwise specified by the manufacturer (reverse donning hard hats).

- Adjust the harness to ensure it always has complete contact with your head while being comfortable

- Ensure any attachments such as lights are compatible with the model of the hard hat.

- Read the instructions carefully regarding helmet use, and in case of any questions or concerns, contact the manufacturer.

To get the most protection from your hard hat, you must ensure it is worn properly. The first thing to look out for is the fit; there should be enough room between the shell and suspension system for proper ventilation, while the helmet should not be too big or too small. Once you have the size right, you can follow the instructions below to learn how to wear your hard hat.

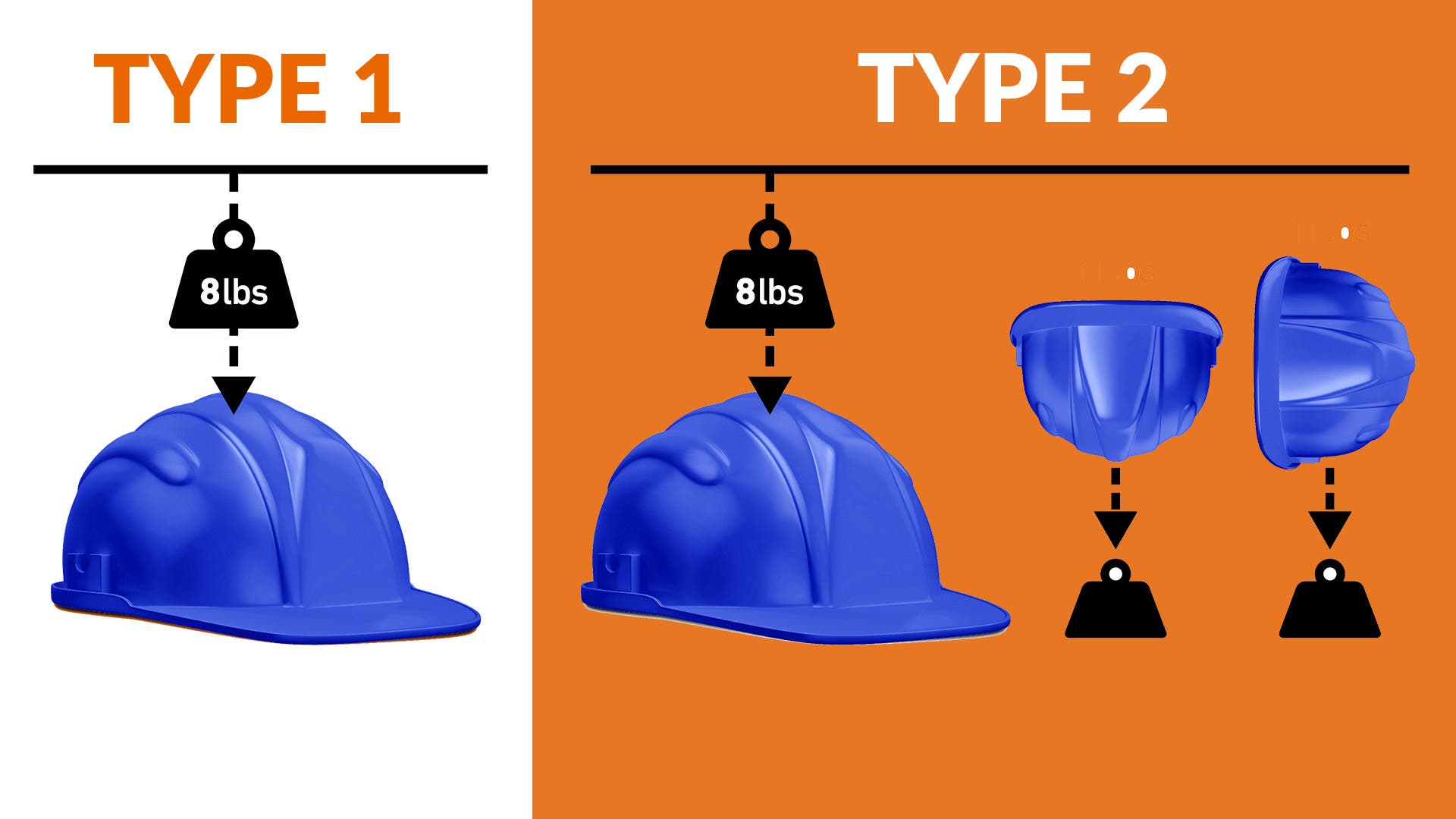

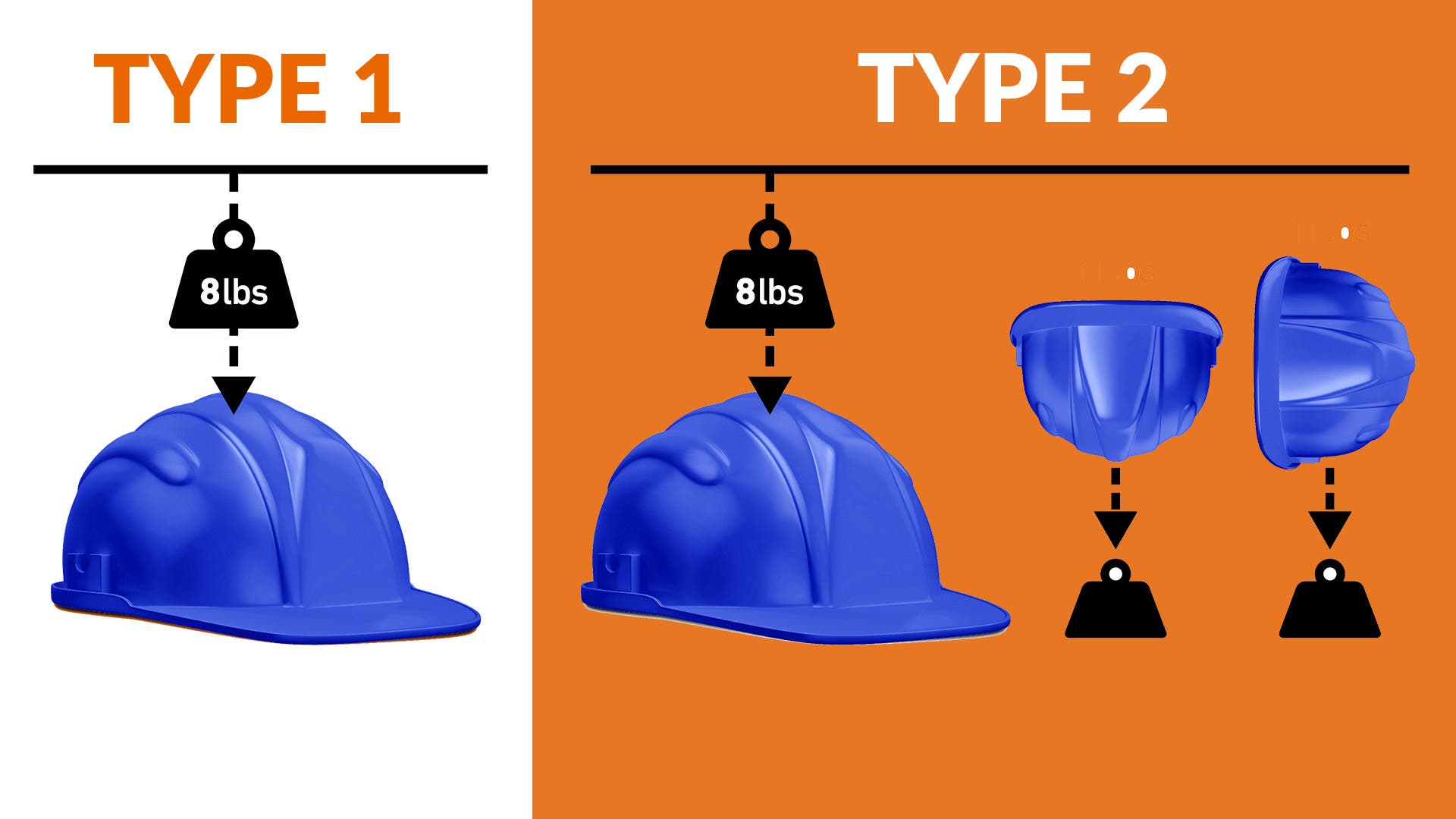

- Type I is used for the general industrial trade, such as construction and factories. This helmet protects the top of the head from direct impact and is commonly used in the United States

- Type II is used in workplaces exposed to constant high heat, such as steel and glass manufacturing. This type offers protection to the top and sides of the head from off-center impact and is more commonly used in Europe

Types of hard hats

Hard hats are also divided into types and classes depending on the degree of impact and protection from electrical hazards. There are two types of hard hats which are defined by the area of the head that is protected.

Another type of helmet known as Type III is also available, which protects the head and is used in bushfire fighting by emergency personnel.

These hard hats are also divided into three classes, each categorized according to the degree of electrical protection they offer:

- Class G (General) hard hats provide electrical protection up to 2,200 volts

- Class E (Electrical) hard hats provide electrical protection up to 20,000 volts

- Class C (Conductive) hard hats do not offer any electrical protection

Additional features and attachments of accessories can also provide greater protection, such as a hard hat face shield, noise-canceling gear, respirator, or work lamp. Other beneficial features can include color coding, which can provide a safer environment at any worksite.

How to Take Care of Your Hard Hat

Regular maintenance can increase the life of your hard hat by helping you identify and mitigate any signs of damage to ensure you are always protected.

- Proper storage can lead to an extended life span so make sure you keep your hard hat in a cool and dry environment. Keep it away from direct sunlight to avoid UV damage.

- OSHA allows hard hat stickers, but you should avoid exposure to chemicals like paints and adhesives not formulated for hard hats, which can cause the shell to crack.

- Clean your hard hat before you wear it. Use mild soap and warm water to rinse, and let it air dry.

- Always inspect the hat’s shell. If the shell looks chalky and loses its shiny finish, it’s time to replace it.

- Replace the harness every year.

- Replace the hard hat per the manufacture’s recommendation (3-5 years), and replace the hard hat if it has been involved an impact or fall, even if it doesn’t show signs of damage.

If the helmet’s structural integrity has been damaged, you need to replace the hat immediately. However, even if you take excellent care of your hard hat, the material deteriorates over time and must be replaced every three years.

Hard Hats Delivered Today

PowerPak has a complete range of head and face protection products including hard hats, construction safety helmets, hard hat accessories, headgear and visors, to help workers prevent traumatic occupational injuries. You can browse the full range and shop online now. Same day delivery available for those in the 10-4 region!