*Disclaimer*

The information contained on this page is for promotional and informational purposes only. All equipment should be used by trained professional tradesmen who have been trained how to use the equipment described on this page, and understand the risks of their work. PowerPak assumes no responsibility for errors or omissions in the use or misuse of any product purchased. In no event shall PowerPak be liable for any direct, special, indirect, consequential, or incidental damages or any damages whatsoever, whether in an action of contract, negligence or other torts, arising out of or in connection with the use of this information or the contents of this page. PowerPak reserves the right to make additions, deletions, or modifications to the contents on this page at any time without prior notice.

One of the most significant issues with protective gear in all fields is the misconception of how it works. Flame-resistant and arc-rated clothing is no exception to the rule. It seems like most of the industry misconceptions revolve around this protective gear category, which is extremely unfortunate considering the high level of hazards involved with handling electrified equipment. There is no room for misconceptions.

We will try and clarify some information regarding FR and AR clothing by helping workers understand their limitations, their intended purposes, and how they are classified.

Flame Resistant Clothing Categories and Arc Ratings

If there is an explosion or an arc blast, workers must have a level of protection beyond the capable hazard of the equipment. The NFPA (National Fire Protection Association) has four arc-rated flame resistant (AR/FR) hazardous risk categories, often called CAT ratings. These ratings are based on the energy delivering capability of the electrical equipment.

- Category 1: This provides a minimum arc rating of 4 cal/cm2 and typically consists of an FR shirt and FR pants or FR coveralls.

- Category 2: This provides a minimum arc rating of 8 cal/cm2, and has 1 or 2 layers, typically consisting of cotton underwear plus an FR shirt and FR pants.

- Category 3: This provides a minimum arc rating of 25 cal/cm2, and has 2 or 3 layers, typically consisting of cotton underwear plus an FR shirt and FR pants, plus FR coveralls; or cotton underwear plus two sets of FR coveralls.

- Category 4: This provides a minimum arc rating of 40 cal/cm2 and consists of 3 or more layers that include cotton underwear, FR shirt, FR pants, and a multilayer arc flash suit.

Choosing the correct category is essential, and you must always err on the safe side – if you are facing an arc rating of 24 cal/cm2, you’ll want to opt for Category 3 protection instead Category 2.

Types of FR Clothing

When you’re checking out FR clothing, you’ll run into plenty of different types.

Flame resistant clothing is made of tough and durable material, and while it will ignite when exposed to flame, it is self-extinguishing. It is inherently designed to resist flames and embers. This means it will not continue to burn, and the fire will not spread throughout the garment.

Flame retardant clothing is generally made of cotton and cotton-blend materials – materials that are not designed to resist flames and embers. However, these are chemically treated and coated to imbue flame-resistant qualities. These chemicals can wash away over time, and the clothing will no longer be flame retardant, more on that later.

Arc rated clothing protects workers from electrical arc flash hazards and is designed to resist ignition in the first place. It is the highest resistance of all FR clothing and is recommended as the equipment of choice for any electrical worker. It can be expensive and bulky, but it's worth it.

Maintenance of Flame Resistant Clothing

Taking care of your FR clothing does require some specific maintenance – you can't wash and dry it as you would just any clothing. Some companies might hire a cleaning service specializing in washing and maintaining FR clothing, or you might have to take it home to do it yourself.

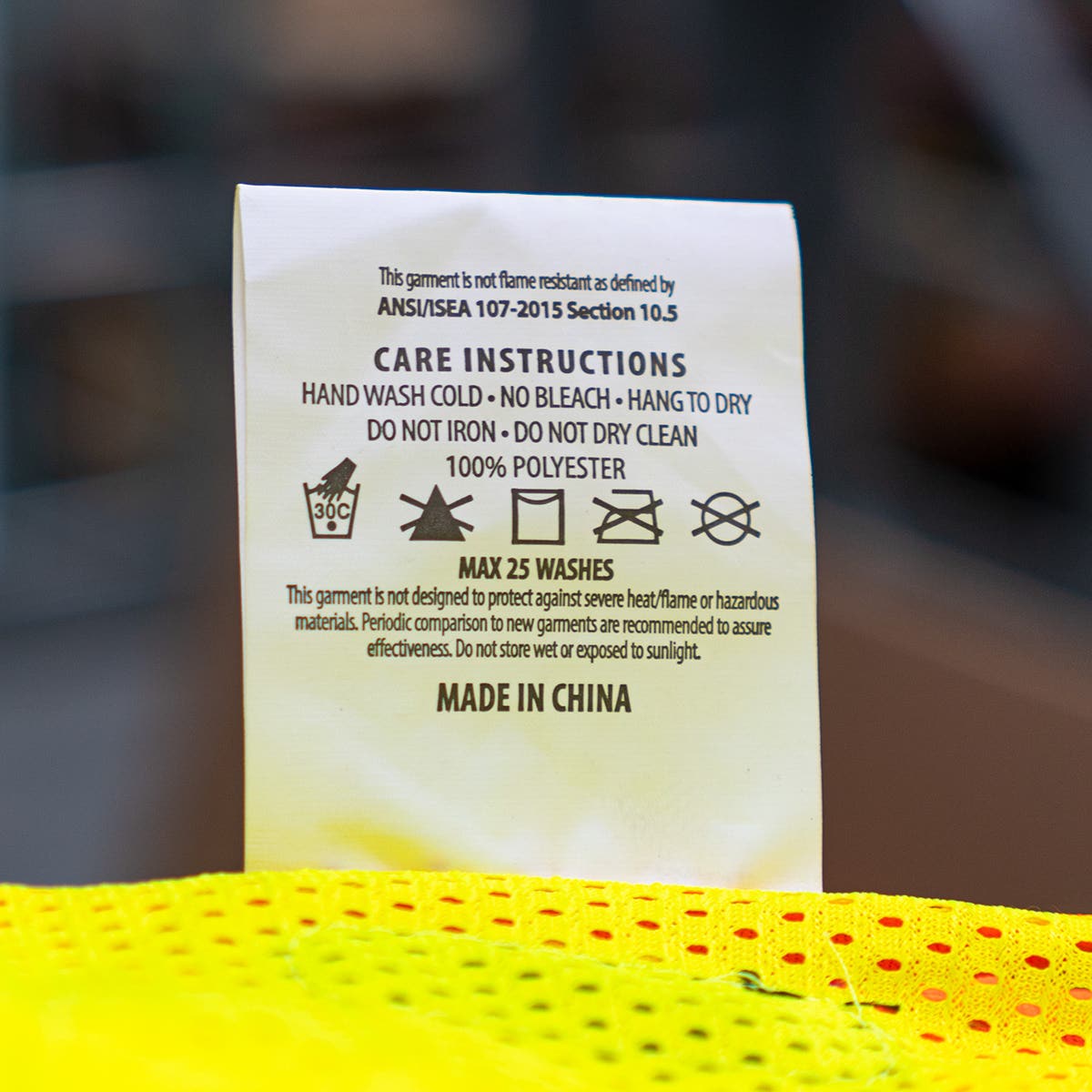

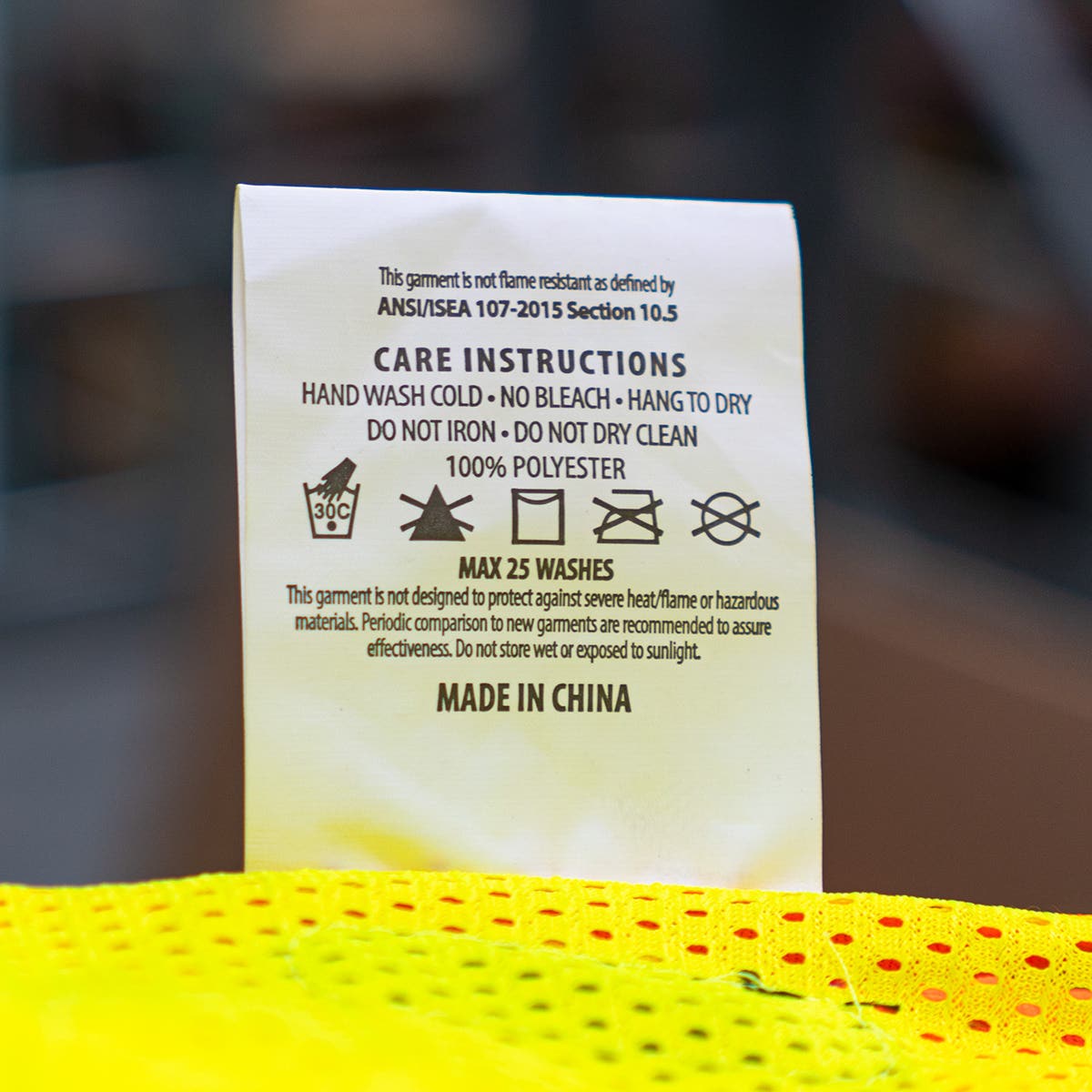

- DO read the label and follow the instructions to the exact wording.

- DO NOT use bleach, as it can reduce the level of flame resistance in the material.

- DO inspect your FR clothing for holes, stretching, or other visible defects regularly.

- DO NOT use starches, peroxides, or other chemicals in cleaning.

- DO wash in small loads.

- DO NOT use fabric softener.

- DO remove from dryer while damp or line-dry to reduce potential shrinkage.

Manufacturers generally provide replacement schedules for their FR clothing. Even if you maintain it at a high level, the flame resistance can fade. Fading is especially likely with flame retardant clothing, where the chemical coating may dissipate after a certain amount of washes. Even if it looks fine, follow the manufacturer's recommendations.

The Importance of FR Clothing

To best understand the importance of FR and AR clothing, you should know how it protects you, its limitations and what could result if you don't have the proper protective gear.

The common misconception is that you're fireproof if you wear FR clothing from head to toe. You can go out and do whatever needs to be done and burn prevention can be put to the back of your mind.

That is woefully incorrect and dangerous to approach a hazardous situation. When exposed to a fire hazard while wearing regular, non-FR flammable clothing, you will be burned by the initial exposure. As you escape the exposure to the flames, your clothing will have caught fire, and your initial burns will continue to get more severe.

If your clothing is flame resistant, you will still be burned by the initial exposure to the fire hazard. As you escape the exposure to the flames, your FR clothing may still ignite, but it will self-extinguish itself much quicker, resulting in less severe burns. The key takeaway is that you will be burned in both cases, but you are less severely burned with FR clothing.

FR clothing is the last line of defense when all other precautions fail. It’s not an excuse to skip those precautions.

The same applies to arc-rated clothing. Even if you are in a CAT 4 suit, you are still susceptible to hazards. Don’t let the bulky, astronaut-look of the gear fool you. Arc flash suits are designed to protect you as much as possible, but there is only so much a suit can do.

If you are exposed to an arc blast, a high-pressure burst of energy, the explosion could throw you across a room, likely causing injury from the force. A CAT 4 suit has an arc rating of 40 cal/cm2. That rating is the arc Thermal Performance Value (ATPV). What that value means is that if you are exposed to an electric arc of 40 calories per centimeter or less, the suit has a 50% chance of protecting you from a second-degree burn or worse. That doesn’t exactly make you Superman. You'll likely incur a minimum of a first-degree burn when exposed to a severe hazard.

Remember, walking away with a first-degree burn is significantly better than the more severe burns that would occur without the protective suit or clothing. It's essential to wear the correct level of protection. OSHA requires employers to “make a reasonable estimate of the incident heat energy to which the employee would be exposed" and provide the appropriate safety measures, including clothing and tools.

FR/AR clothing protects you from fire, arc flash, and arc blast, but they aren't designed to protect you from electrical shock. High voltage gloves are an important piece of PPE for working with electrical equipment. These are rubber insulating gloves that help to prevent getting shocked if you suddenly become part of a circuit. The rubber gloves should be worn as part of a three-glove system. The first layer should be liners that provide warmth and comfort or act as moisture wicks to keep hands dry. The second piece is the high-voltage glove itself. Finally, leather protectors should be worn over the rubber gloves to prevent cutting the rubber material and affecting its capabilities.

High-Voltage Gloves

These gloves, paired with insulated tools and dielectric equipment, are a great measure to help protect workers from electrical hazards.

High-voltage gloves have different classifications than flame-resistant clothing. These classifications spell out the maximum rating of each class – it never hurts to "class up" from the voltage you are exposed to, but the gloves are tested well beyond their rated voltage, so you’ll be good either way.

- Class 00 — Maximum use voltage of 500 volts AC/proof tested to 2,500 volts AC and 10,000 volts DC

- Class 0 — Maximum use voltage of 1,000 volts AC/proof tested to 5,000 volts AC and 20,000 volts DC

- Class 1 — Maximum use voltage of 7,500 volts AC/proof tested to 10,000 volts AC and 40,000 volts DC

- Class 2 — Maximum use voltage of 17,000 volts AC/proof tested to 20,000 volts AC and 50,000 volts DC

- Class 3 — Maximum use voltage of 26,500 volts AC/proof tested to 30,000 volts AC and 60,000 volts DC

- Class 4 — Maximum use voltage of 36,000 volts AC/proof tested to 40,000 volts AC and 70,000 volts DC

There is also the question of whether they are resistant to ozone or not – gloves labeled as Type I are not resistant to ozone, while Type II gloves are. Ozone resistance is necessaary in work zones with high pollution levels because ozone exposure will degrade rubber.

Just like FR clothing, high-voltage gloves need special care and maintenance. They should be inspected for tears, holes, ozone cuts, and other issues before every use. They should also be checked for swelling that can stem from chemical contamination, specifically exposure to petroleum products. Keeping them in specially-designed glove bags in a dry, climate-controlled place is the best option.

High-voltage gloves also need to be tested before being put into service and periodically to ensure they retain their electrical resistance. They must be tested before the first issue and then every six months afterward to ensure the insulation is as it should be. You can find your nearest testing lab here.

Never Cut Corners When it Comes to Safety.

Safety is not something you should skip over or ignore. Working with electricity requires a fair amount of effort to ensure you are safe from harm, but seemingly tedious safety practices need to be taken seriously. Year after year, there are thousands of workplace electrical injuries and hundreds of deaths. To ensure the safety of your workers and protect them from electrocution and fire when performing hazardous work, make sure they have the correct PPE. Shop our range of flame-resistant clothing and high-voltage rubber gloves now!