*Disclaimer*

The information contained on this page is for promotional and informational purposes only. All equipment should be used by trained professional tradesmen who have been trained how to use the equipment described on this page, and understand the risks of their work. PowerPak assumes no responsibility for errors or omissions in the use or misuse of any product purchased. In no event shall PowerPak be liable for any direct, special, indirect, consequential, or incidental damages or any damages whatsoever, whether in an action of contract, negligence or other torts, arising out of or in connection with the use of this information or the contents of this page. PowerPak reserves the right to make additions, deletions, or modifications to the contents on this page at any time without prior notice.

Table of Contents

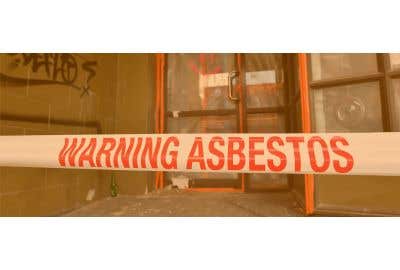

The Risk of Asbestos

If you’re young, you may be unfamiliar with asbestos. Pre 1980, asbestos was the go-to solution for a wide variety of building needs. It was mixed in with cement, added to plastics, it was used for soundproofing, its natural heat resistance made it great for fireproofing, but it was most notably and widely used for insulation.

In North America, it was widely used to insulate homes, pipes, boilers, and anywhere else insulation was needed. It can still be found in many homes past a certain age.

Imagine the public shock when it was discovered that asbestos exposure is a known cause of mesothelioma, lung cancer, and other cancers and diseases. Like with most cancer-causing materials, the damage to your body takes time to become apparent, but once it begins, there is no treatment to reverse the damage.

The inhalation of asbestos fibers is what causes asbestos illnesses and cancers. When disturbed, the fibers get into the air and collect in your lungs and airways. Prolonged exposure increases the risk of illness. So, workers handling asbestos, conducting asbestos abatement, or doing any work in an environment with asbestos need to take extreme precautions.

Respirator Filter Rating

The common misconception is that any mask, filter, or respirator will work. Many workers are operating under the assumption that they will be fine as long as they have something covering their mouth and nose.

Bandanas, neck gaiters, and general use face masks will NOT protect you from asbestos.

KN95, N95 mask, or any other disposable dust mask will NOT protect you from asbestos.

To protect from asbestos, you need a respirator that can filter a minimum of 99.97% of particles that are 0.3 micrometers large.

To achieve that level of filtration, you need either a half-face or full-face respirator paired with a NIOSH-rated N100, R100, or the more common P100 filter. The P100s are colored purple per the NIOSH color-coding system for respirator cartridges.

P100 is a high-efficiency rating and the ideal solution for protection against asbestos inhalation. Often the P100 rating is paired with other ratings and features to create respirators designed to handle a wider variety or more complex projects.

Full Face Respirator vs. Half Face Respirator

At first glance, workers often think you pick a half-face or full-face respirator, depending on whether you need eye protection. Sure, a full-face respirator has a built-in shield, but that's not the deciding factor. It goes without saying, but you always need eye protection.

Different classes of respirators have different APFs (Assigned Protection Factors). APF is a measurement of how well a respirator performs. Both a half-face respirator and a dust mask have an APF of 10. Full face respirators have an APF of 50. This means you can expect to be exposed to 1/10th or 1/50th of the contaminated air. It’s important to understand that respirators are not 100% effective and knowing how effective each option is will guide you in determining which one you need.

For example, while repairing a sewer pipe in an environment with asbestos insulation, you may want to use a P100 multi-gas respirator filters, which will filter 0.3+ micrometer particles and various gases, including hydrogen sulfide and ammonia. This multi-purpose filter gives workers the protection they need for projects with a wide variety of hazards.

A worker will use a full-face respirator in environments with high atmospheric contaminants and require increased protection to stay below the permissible exposure limit (PEL).

Let’s break this down, the best way to decide what respirator to use is to know the permissible exposure level for your hazard (dictated by OSHA) and what levels of that hazard are present in your workplace (measured by risk assessment report). When you have those two numbers, you can pick your respirator type (full-face vs half-face) based on the APF for the type.

Using asbestos as an example, per OSHA, asbestos has a PEL of 0.1 fibers per cubic centimeter. For asbestos, you need to hire a surveyor to conduct an asbestos risk assessment to find the level of the asbestos hazard.

Since a half-face respirators with a P100 filter has an APF of 10 (1/10th exposure), you can use a half-face if the risk assessment comes back at one fiber per cubic centimeter or less.

Full-face respirators have an APF of 50 and can be used in environments with an APF of 5 fibers per cubic centimeter or less.

SARs do not require a P100 filter because they pull air from an air pump or compressor tank outside the contaminated air zone. There are a couple of different configurations for this system.

At the basic level, a worker is wearing a full-face mask that is connected to a hose, and that hose runs to an air pump or air tank that supplies clean air directly into the mask. This supplied-air respirator configuration is popular because it's easy to setup, protects from a high level of contaminants, and is cost effective.

It's important to know this information because it prevents you from spending money on respirator equipment you don't need. More importantly, it prevents you from using equipment that won't protect you.

Other Respiratory Protection Options

Powered Air Purifying Respirator (PAPR)

This system involves a full head helmet with a hood and a powered pump. How PAPR operates varies between models and manufacturers. Most commonly, the air is pulled in by a pump. The air is filtered and routed through vents on the inside of the helmet forced downward.

The filtered air fills the helmet and is pushed out the bottom through the neck hole. The constant air pushing out through the neck hole prevents contaminated air from getting in. This style of PAPRs are considered loose-fitted and don't require fit testing, which we will get into later. PAPRs are more commonly seen in hospitals and laboratories.

Powered Air Purifying Respirators can be used in environments with up to 100 asbestos fibers per cubic centimeter.

A more advanced system has the same setup but includes a 5-minute cylinder. In normal use, this system works just like the basic level setup, but if the air pump fails, the user can switch to the 5-minute cylinder giving them time to escape the contaminated air zone.

Both supplied-air respirator systems can also be used in environments with 100 asbestos fibers per cubic centimeters.

Self-Contained Breathing Apparatus (SCBA)

This system is ideal for work that requires clean air supply without the limitations of being connected to a hose, like with SAR.

In this system, the user carries a tank of compressed air that feeds clean air into the full-face mask. Since the tank does not pull in more air, this system works for as long as there is air in the tank. This is a popular system with firefighters and emergency responders.

Self-contained breathing apparatus can also be used in environments with up to 1,000 asbestos fibers per cubic centimeter.

Importance of Properly fitted Respirator

Respirators need to be securely sealed to your face because if air can get around the seal, it defeats the purpose of the respirator. The OSHA guidelines on fit checking a respirator are comprehensive. This process requires levels of attention.

User Fit Test

Every time you put on your respirator; you need to conduct a user fit test. After you put the mask on and it is comfortably secure, you will conduct a negative pressure test and a positive pressure test.

Negative pressure tests require you to block the filter inlets with your hands and then breathe in and out, paying attention to air coming in around the edges of the mask. A properly fit mask won’t have air leaks.

A positive pressure test requires you to block the exit vent on the mask with your hand and, again, breathe in and out. Now you’re paying attention to any air escaping around the edges of the mask. A properly fit mask won’t have air escaping.

Employer Fit Test

OSHA requires employers to fit check respirators at least once annually. These tests need to be conducted by qualified individuals with proper test training. There are two different test methods, quantitative and qualitative.

Qualitative respirator fit tests require users to put on their respirator and then place a fit test hood over their head. A tester sprays a flavored testing agent into the hood, and the user reports if they can taste the testing agent through the respirator or not.

Quantitative fit tests require a machine or device that can measure the air quality inside and outside the respirator. The machine calculates how well the respirator is performing.

Both tests can be used for positive pressure respirator systems, like PAPR, SAR, and SCBA.

For negative pressure respirators, like half-face P100 filtered masks, full face P100 filtered masks, N95, or KN95 masks, a qualitative test can only be used on respirator systems intended for environments with less than ten times the permissible exposure limit. Otherwise, a quantitative test must be conducted.

For asbestos, the PEL is 0.1 fiber per cubic centimeters. So, respirators used in atmospheres with less than one fiber per cubic centimeter can be qualitatively tested. Anything above one fiber per cubic centimeter needs to be quantitatively tested.

Beard Lovers Take Flight

We saved this little tidbit for the end. Most respirator systems cannot perform correctly on anything other than a clean-shaven face. Take some time and come to terms with this now, and be sure to add a beard trimmer to your cart when you order your respirator.

Unfortunately, PowerPak does not offer beard trimmers or shaving razors at this time, but be sure to visit PowerPak.net or contact us for all of your respirator and safety equipment needs.