*Disclaimer*

The information contained on this page is for promotional and informational purposes only. All equipment should be used by trained professional tradesmen who have been trained how to use the equipment described on this page, and understand the risks of their work. PowerPak assumes no responsibility for errors or omissions in the use or misuse of any product purchased. In no event shall PowerPak be liable for any direct, special, indirect, consequential, or incidental damages or any damages whatsoever, whether in an action of contract, negligence or other torts, arising out of or in connection with the use of this information or the contents of this page. PowerPak reserves the right to make additions, deletions, or modifications to the contents on this page at any time without prior notice.

We can't tell you which lifting slings you need for your specific job. No one can without knowing all the parameters of the load and the lift.

What we can do is give you some useful information on lifting slings that will help you narrow down the selection. There is a very wide selection of sling types but narrowing it down is easy if you know the load amount, how fragile/delicate the load is, and a few other factors.

Let’s get into it.

Types of Construction Lifting Slings

At PowerPak, we split construction lifting slings into four categories: lifting chains, wire rope slings, flat web slings, and round slings.

Lifting Chains

Lifting chains are the most popular of any of the options. They come in various configurations, with different hook options and leg quantities.

One of the main reasons chains are the go-to lifting options for most workers is that they are incomparably durable. They can take a beating and work in extreme conditions without issue.

Also, chains are versatile. You can get chain slings in configurations between single-leg, up to quad leg, and chain slings are one of the only types of slings that are both adjustable and reparable. If you have a damaged chain link, the chain link can be replaced, and that sling can be re-certified and put back into service.

Chain slings have setbacks as well. First, chains are hard and heavy, which is a great combination for causing damage. If you are lifting or working with delicate or damageable items, a chain sling can quickly become an issue. The chain can scratch finished surfaces, crush non-re-enforced objects, and dent surfaces with a slight bump.

Another issue is that chain slings are currently subjected to the most regulations of all sling options. Lifting sling regulations are covered by OSHA (Occupational Safety and Health Administration) and ASME (The American Society of Mechanical Engineers). Specifically, ASME B30.9, which is reviewed and updated every few years.

A decade ago, sling regulations were almost exclusively based on chain slings, with each update, and as the market shifts to adopting other sling options, the standards have become more encompassing.

Cost is another factor with lifting chains. For overhead lifting, you are required to use grade 80 chains or higher. You don't have to completely understand what a chain grade is to know the 80+ rule roughly translates to higher costs. Picking lifting chain slings is a costly option, but chains could be economical, depending on your lifting needs. Buying one expensive lifting chain sling could cost less than continually replacing less expensive wire rope slings or other options.

Wire Lifting Slings

Wire Rope Slings are also very popular. The construction of wire rope slings consists of wires wound together into strands and strands wound together into rope. The more wires and strands, the thicker the rope, and the diameter will determine both the flexibility and lifting ability of the wire rope sling. The construction of wire rope slings is usually steel in accordance to ASTM guidelines.

Wire lifting slings have eyes on both ends. The eye construction can vary, but you'll find rope slings with flemish eyes in most cases. This is where the strands are split up and re-wound back together in a loop and locked in place by swedging a metal cap over it.

These slings are popular because they are lighter and cost less than chain slings. Unfortunately, they have a fraction of the lifting limit compared to chain slings. Worker's not lifting loads that require chain slings can enjoy the ease of use of wire rope.

The stiffness of the rope makes it very easy to rig up for lifting. If you need to slide a sling under a load with low clearance, you can easily feed the cable through. The same task would be difficult with a chain.

Additionally, wire rope slings come with different sized “eyes”, different rope lengths, and different hardware options at each end (if any). Also, similar to chain slings, wire rope slings can come in multi-leg options.

Like any sling option, wire lifting slings have their pitfalls, and one of the more significant issues users run into is they can become easily damaged when lifting certain loads that normally aren’t a problem for other types of slings. If the wire sling gets kinked or pinched, it will render it unusable. Also, if the individual wire begins to break and fray from ware or extreme tension, the sling has to be removed from service.

Like chains slings, wire rope can cause damage to fragile or delicate items and can scratch unprotected surfaces.

Flat Webbed Lifting Slings

Flat Webbed Slings sometimes called synthetic slings are growing in popularity as technology advances. You’ll find that Flat Lifting Slings are made of either polyester or nylon. Both material types have specific uses.

The main difference between nylon and polyester slings is how those materials react when exposed to specific chemicals. Nylon has alkaline resistance and does not react negatively if exposed to oil.

Polyester, on the other hand, is resistant to bleaching agents and acidic chemicals. You'll want to pick your lifting gear based on the potential chemical exposure to your sling.

Stretch is also a factor with both types of slings. Polyester is rated to stretch up to 3% and nylon will stretch 6% - 10%. This stretch amount needs to be accounted for when close to the lifting height limit or a low headroom situation.

You'll often find polyester and nylon web slings with an eye on each end, but you can also find them in infinite loops or attached hardware. The eye-to-eye configuration is the most popular because it is very versatile. The eye-to-eye slings easily allows you to set up vertical, basket, and choker lifts.

The lifting capacity of webbed slings is lower than wire rope slings. They do have the advantage of being very good at conforming to the shape of the object they are lifting, and their nonabrasive material makes them ideal for lifting loads you want to protect from damage.

The pitfall with webbed slings is the edge of the sling might run up against a corner or an abrasive surface, and the webbing might start to fray. If that happens, the sling must be removed from service. Manufacturers have addressed this issue with the option of an edge guard. An edge guard is extra protective material sewn over the edges of the sling. This material does not serve any structural support, so if it begins the fray, it does not affect the lifting ability of the sling. These are called Edge-Wrap Slings.

Round Lifting Slings

Round Slings, also a type of synthetic sling, are perfect if you like the idea of edge guard but are disappointed that it only covers the edge. Like web slings, they are constructed of high-strength polyester or nylon, and they are additionally protected by a jacket surrounding the entire sling.

These slings are incredibly lightweight, with excellent lifting capabilities. In most comparisons, they are similar to web slings.

Round slings are most commonly found as a continuous (infinite) loop, but you can also find eye-to-eye round slings. The full wrap jacket makes these the perfect lifting option for items you want to protect from scratches or damage.

The jackets are usually color coded for lifting rating, making it easy to pick the correct sling for the job and quickly identify if the wrong sling is being used.

The pitfall of both web slings and round slings is that it is not advisable to use these slings on loads with sharp edges. Regardless of how strong the fibers are, they aren't metal, and they have limitations.

Tags & Labels

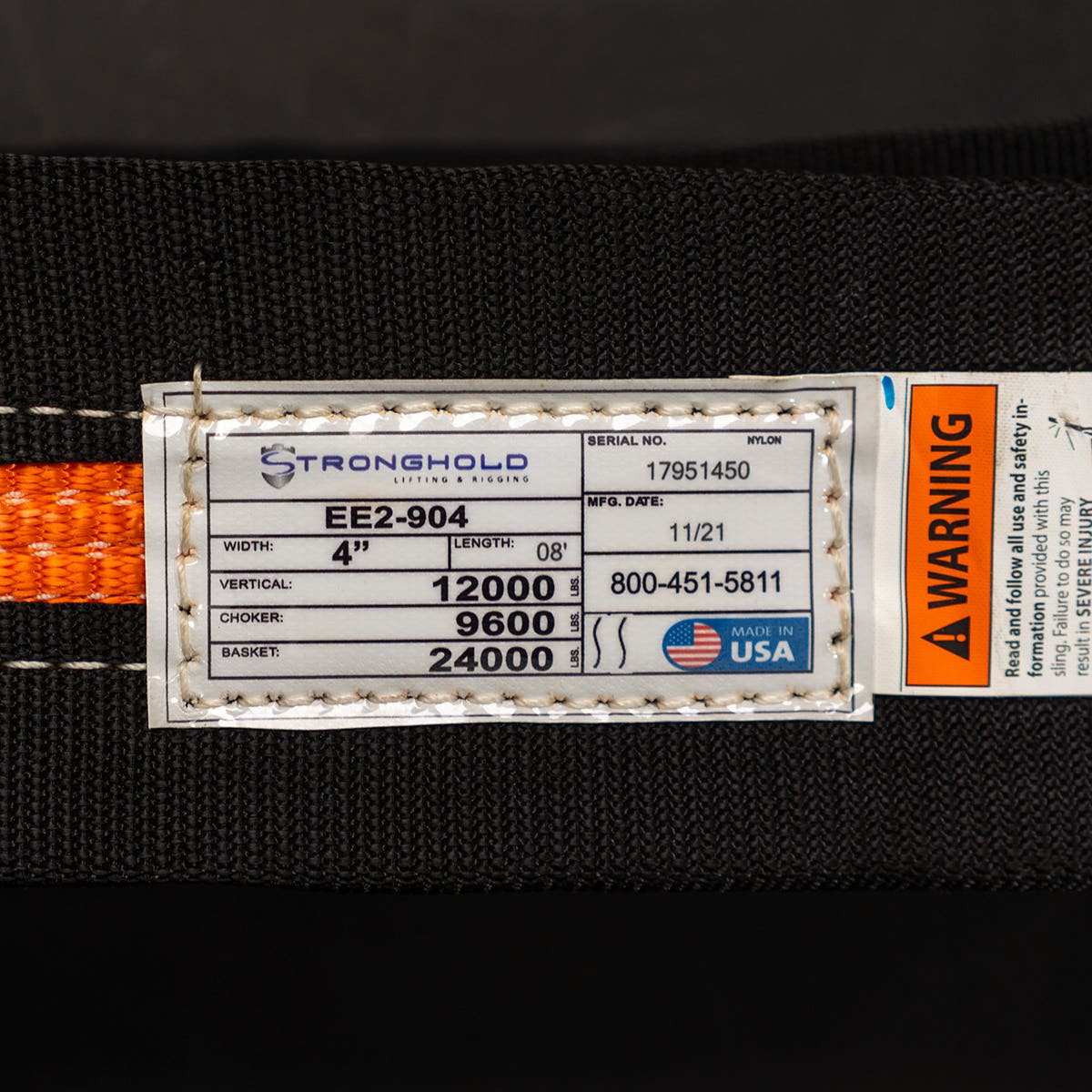

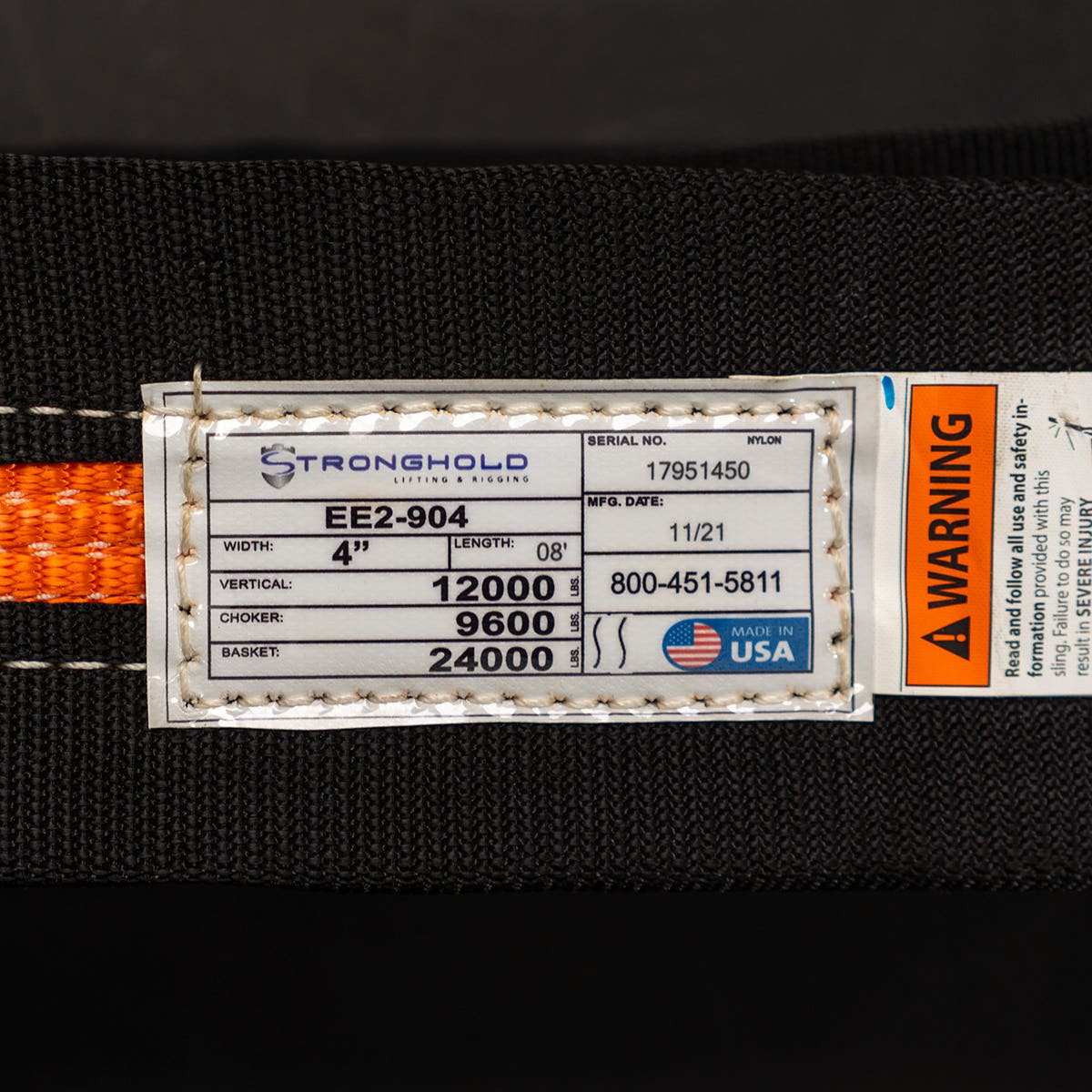

OSHA regulation 29 CFR 1910.184 requires that every sling needs to have a tag or label. They use the word "identification," but however you describe it, the information needs to be present and legible. The information required differs depending on the sling type, for example, chain slings are required to display the grade, and web slings need to identify their width.

Information you can expect to see on all lifting sling tags include rated weight capacity for different lifting methods (vertical/straight lift, choker, basket, quad, etc), manufacturer info, and length.

Length is measured from bearing point to bearing point. Meaning you measure from the two most extreme edges, including any hardware. This can be a cause of confusion with chain or wire rope, as workers may discount the added length of the hooks or rings. The length of the hardware is included in the total length of the sling.

Inspection

Before each use (OSHA 1819.184(d)), every sling should be inspected. This is something that is preached with web and round slings a lot, but it applies to all slings. Inspections are simple, and there is no real reason to skip it. You simply need to visually examine the sling for any defects or damage. For web slings, you are looking for discoloration or frayed edges. For wire rope slings, you are looking for kinks, twists or frayed wire. For chains and for hardware on any sling, you are looking for dents, deformation or stress marks. If you find any issue with your sling, it must be removed from service.

Additionally all slings are required to undergo an annual/periodic inspection (OSHA 1910.184(e)(3)(i)) in which a designated individual will thoroughly check the sling for defects or issues.

The Right Sling for the Job

As mentioned at the top, narrowing down what sling you need is not as hard as it initially looks. If you know the delicacy or how easily your load can be damaged, you can potentially eliminate half your options. Taking sharp edges and load weight into account, you can quickly narrow your needs down to one sling category.