*Disclaimer*

The information contained on this page is for promotional and informational purposes only. All equipment should be used by trained professional tradesmen who have been trained how to use the equipment described on this page, and understand the risks of their work. PowerPak assumes no responsibility for errors or omissions in the use or misuse of any product purchased. In no event shall PowerPak be liable for any direct, special, indirect, consequential, or incidental damages or any damages whatsoever, whether in an action of contract, negligence or other torts, arising out of or in connection with the use of this information or the contents of this page. PowerPak reserves the right to make additions, deletions, or modifications to the contents on this page at any time without prior notice.

Every time you get into a car, you put on a seatbelt. Anytime you step onto a work boat you should wear a life jacket. It should be the same instinct in your brain. In the event of an on-water accident, that life jacket is your last line of defense to keep you from drowning.

Before we get into this, lets lay some groundwork here. A lot of people use the term life jacket and personal floatation device interchangeably. That’s not wrong, but it’s also not exactly right. Personal flotation device (PFD) is a category, and a majority of that category consists of types of wearable PFD, commonly known as life jackets, but not all PFDs are lift jackets.

We will get into all of that soon enough. If you read nothing more, the main takeaway here is to always wear a lifejacket, make sure it’s the right type, make sure it fits, and always inspect it before you wear it. If you can confidently check those boxes, you’ll do alright. If not, read on.

Types of PFDs

Personal Flotation Device “types” is the topic most of you are here for. There are five types of personal flotation devices; not all types are wearable, aka life jackets.

- Type I is the top tier for wearable PFDs. These are designed for offshore, deep water, or rough water conditions. Offshore meaning you are in open water with no shore in sight. Type I vests are designed to flip a person into the faceup position if unconscious. They require a minimum buoyancy rating of 22lbs for foam-filled options and a minimum of 33.7lbs of buoyancy for inflatable options. See the next section to better understand these buoyancy ratings.

- Type II PFDs are the next tier down. They require a minimum buoyancy rating of 15.5lbs for foam-filled type II PFDs and a minimum of 33.7lbs of buoyancy for inflatable options. Type IIs are also designed to flip you in the faceup position.

The difference between a Type I and Type II is the design. Type I's are usually of a life jacket or vest that you put on the same way you would with a normal jacket or vest, with arm holes and a front zipper. Type II attaches around your neck and is strapped in around your body. Type II are usually known to be cumbersome and are difficult to work around. For a long time, these were not a preferred option for workers because they were awkward to work around, but as newer designs have come out, they have become smaller, lighter, and easier to wear.

- Type III's are designed for inshore, meaning you are out on the water and can still see the shore. These require a minimum buoyancy rating of 15.5lbs for foam-filled Type III PFDs and a minimum of 22.5lbs of buoyancy for inflatable options.

These are ideal for inshore utility workers, river crew, construction barge workers, etc. They are worn like a vest, usually comfortable and easy to wear. They are NOT designed to flip unconscious people in the faceup position. Type III PFDs are intended for calm water where rescue operations can be swift, and the auto flipping feature is unnecessary.

- Type IV is where things get a little different. These are known as throwable devices. When people think of type IV PFDs, the first example that comes to mind is a traditional ring buoy, but other examples include rescue throw bags and floatation cushions. Type IV PFDs are required to have a minimum of 16.5lbs of buoyancy.

- Type V's are specialty PFDs. These are created and used for specific purposes. These PFDs state their buoyancy rating and can be used in various applications depending on the specific PFD.

Buoyancy Ratings

In the previous section, we discussed the minimum buoyancy ratings for the different types of PFDs. These ratings range from 15.5 lbs. to 33.7 lbs. Without being presumptuous, it is safe to say that if you are reading this, you weigh more than 33.7 pounds.

So, why such a low-weight rating? There are a couple of reasons. It doesn’t take much aid to help keep a person afloat. The human body is mostly comprised of buoyant substances like water, air, and fat. The PFD only needs to help keep the dense body material afloat, and specifically only your head. It's fine if your legs and torso remain under the surface. You’ll find that 15-30 lbs. is more than enough buoyancy to keep your head above water.

Foam vs. Inflatable

You may have noticed each type of vest has two different buoyancy rating minimums. One for a foam-filled vest and one for an inflatable vest.

Which one is better?

Well, for commercial use, you'll likely find that most of the vests are foam vests. Foam vests are readily available, have fewer parts that can break or malfunction, are easier to maintain, and do not require any additional steps from the user. So, if a worker is knocked unconscious and falls overboard, they don’t need to pull a rip cord or blow into a straw. The vest will keep them afloat until they are rescued.

Inflatable vests are going to be lighter and more comfortable to wear. When not inflated, they lay flat and out of your way, making it easy to work. When inspecting an inflatable vest, you need to check the indicator. The indicator will either read green if the inflator is in good working condition or red if not. It is very important to check this indicator before every use.

For these reasons, generally speaking, a foam-filled vest is the better option for commercial use.

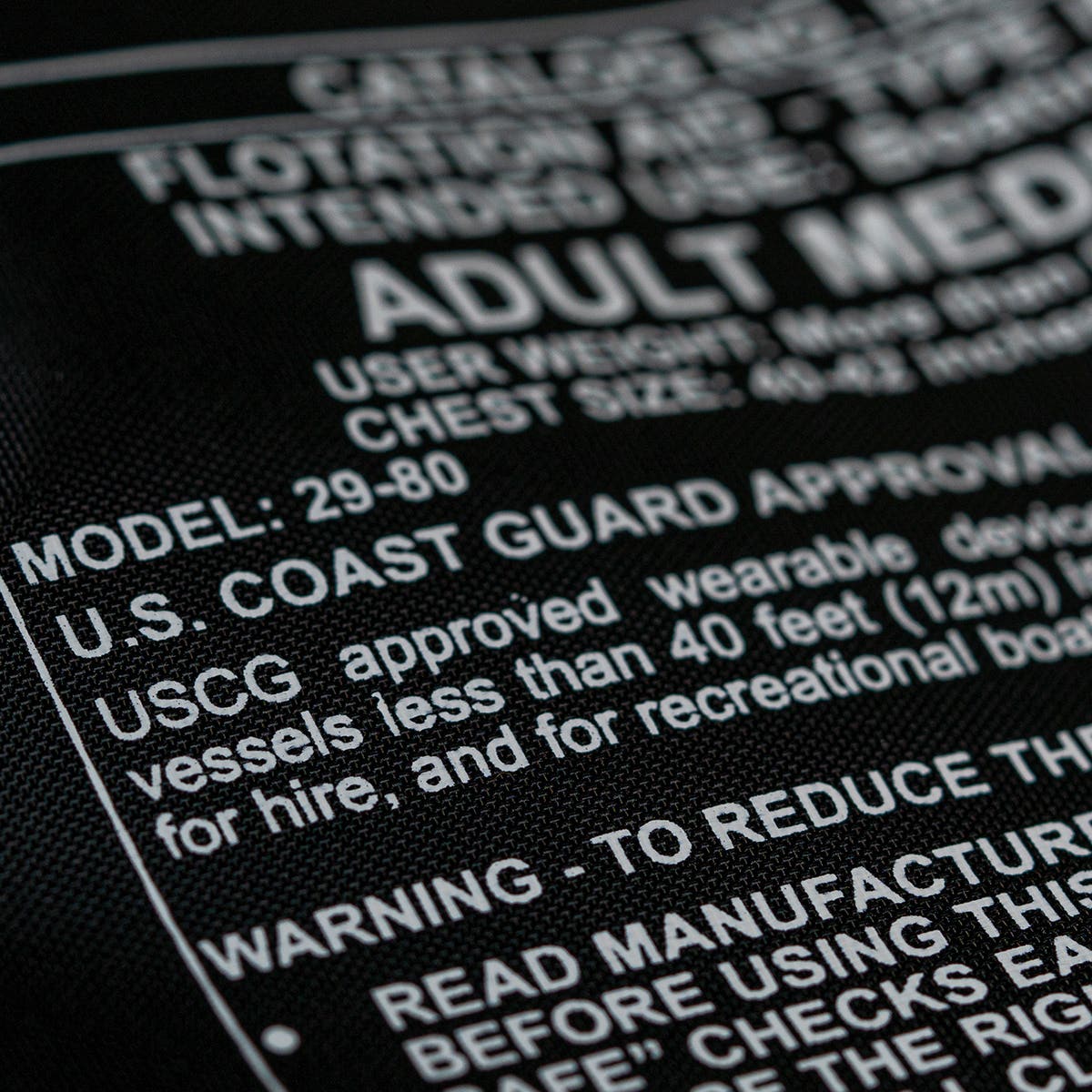

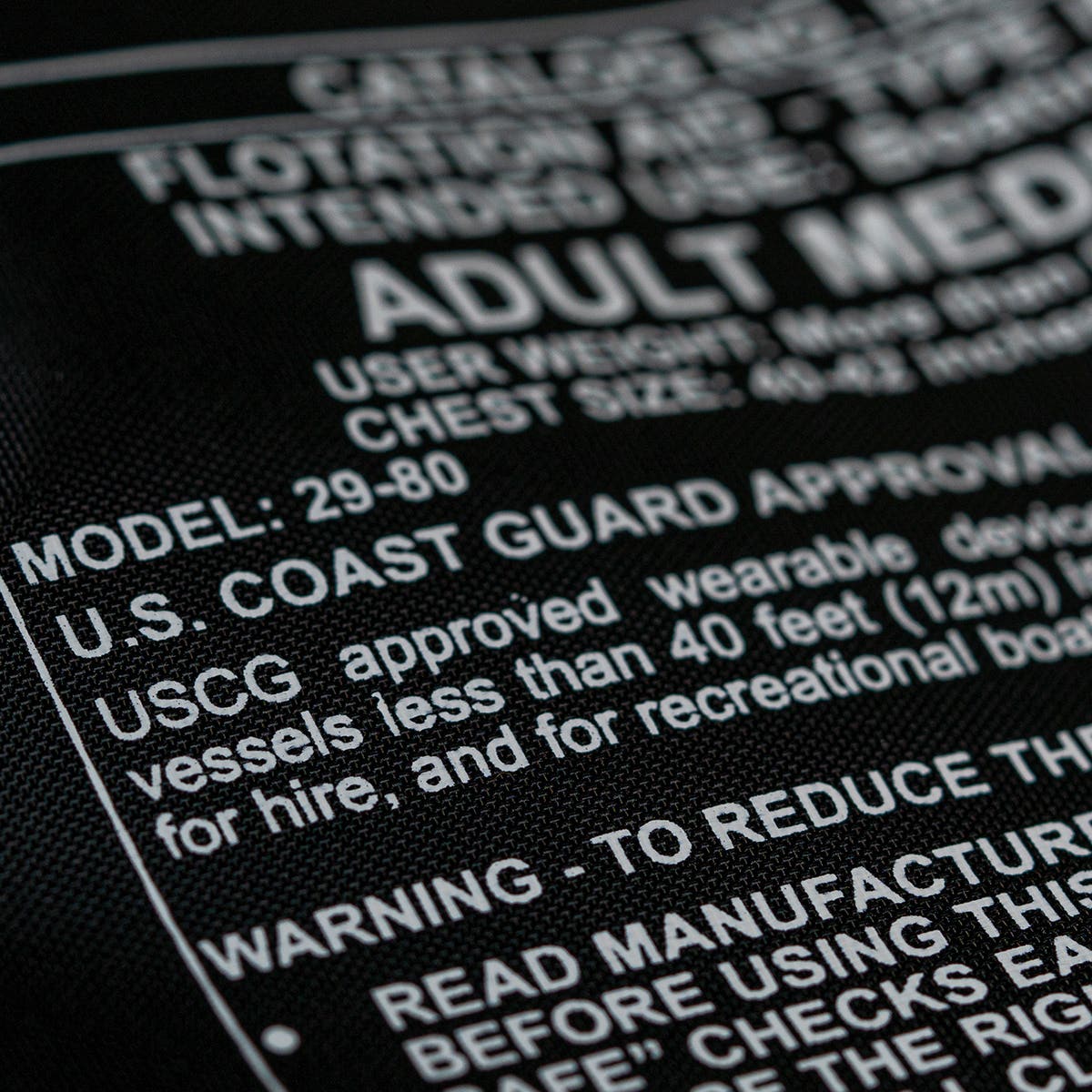

Wearable PFD Sizing

Different manufacturers have different sizing guides. A general rule of thumb when picking a vest sight unseen is to base your selection on your chest size rather than your weight. Most vests are adjustable, so if you are in the ballpark, you should be able to tighten or loosen as needed.

Fit checking a vest is easy. After you put the vest on and tighten it until it feels secure, raise both hands above your head and have someone else pull up on the vest. If the vest raises past your nose, mouth, or higher, the vest is not tight enough or is too big. You want the vest to stay put or not get past your chin.

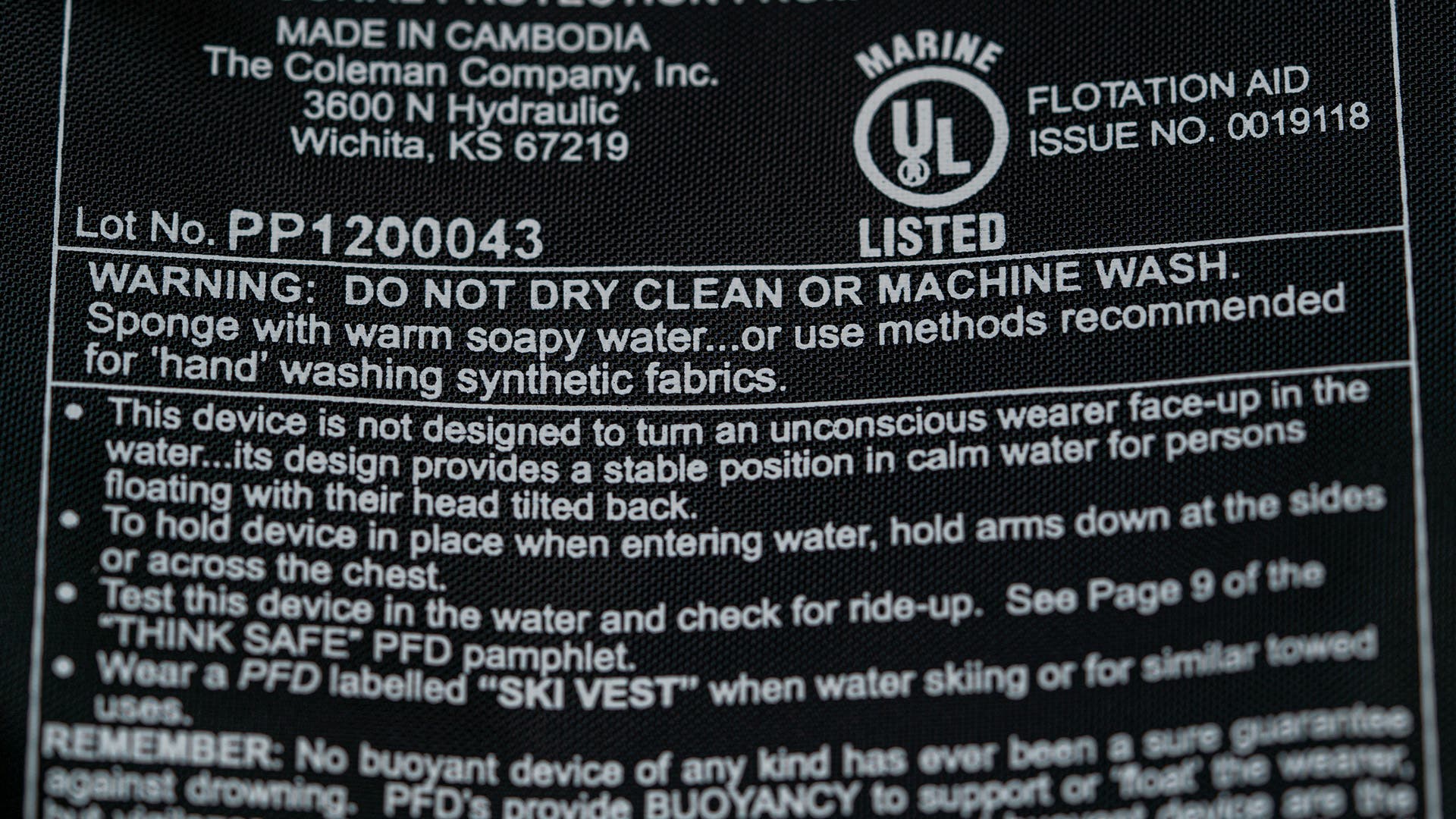

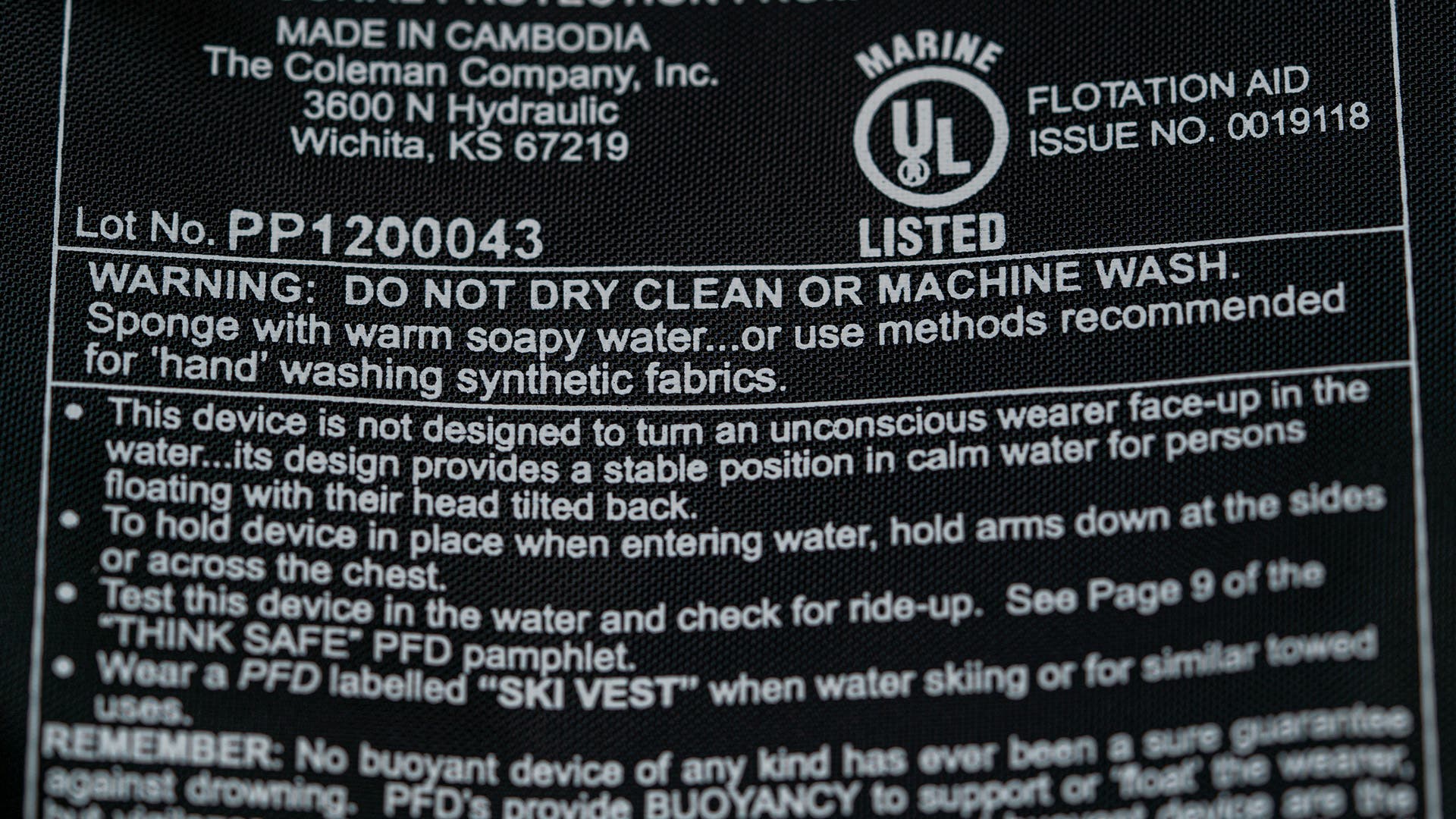

Care Instructions

Obviously, check the tag. Generally, you don’t clean a life jacket the same way you clean your other laundry. You shouldn’t put them in a washing machine, and you definitely shouldn't put them in a dryer. The best method would be to hand wash and air dry. Once dry, it should be stored in a cool dark place.

Improper washing and storage can cause the PFD to shrink, become discolored, or misshapen. If there are any issues with your PFD, you should take it out of service.

Other than the care instruction, the tag on a PFD will also include an approval rating from the United State Coast Guard. All PFDs, regardless of if they are used on a small one-person canoe or an aircraft carrier, must be approved by the US Coast Guard.

The tag should also state if the PFD is approved for commercial or recreational use. In both cases, the approval process involves the manufacturer sending the PFD to a US Coast Guard-approved lab for testing. The key difference is that the US Coast Guard is much more involved in creating and approving new commercial PFDs.

The process is not a "one and done" situation. After a vest is approved, the US Coast Guard-approved lab conducts a follow-up inspection to ensure the actual production vest meets the same standards as the vests sent in for testing. Things change when you start mass producing, and the US Coast Guard wants to make sure the one thing that doesn’t change is the safety of these vests.

The United States Coast Guard Approval

The manufacturer is also required to create a quality control program that involves regular inspections, maintenance, and detailed records that can be submitted for review if called upon.

OSHA Regulations for Life Saving Equipment

Most of the OSHA regulations support the US Coast Guard requirements. They specify that any vessel over 200 ft long must have a minimum of three 30-inch ring life buoys, and any vessel under 200 ft must have at least one 30-inch ring life buoy. Additionally, all buoys must be equipped with at least 90 feet of rope. OSHA additionally requires all PFDs to be inspected before use for any defect or dry rot.

OSHA also requires a minimum of one US Coast Guard-approved wearable PFD per person onboard and at least one readily available rescue ladder.

Maritime Safety

Everything you need to stay safe while working on the water. PowerPak carries a curated selection of maritime safety gear, with a primary focus on inshore work. Our selection includes Type III Personal Flotation Devices, 30” ring buoy, ring buoy rope, rescue bags, whistle, and vest lights.

Contact us today to see how we can help you.